Headlines

- What’s the difference between Case Hardening and Through Hardening?

- The three-step process for drilling completely accurate and smooth holes.

- What it takes to supply top motorsport teams.

- Precision Engineered Solutions That Reduce Production Cost and Time.

- How composites, and an unlikely companion, make hypersonic flight a possibility.

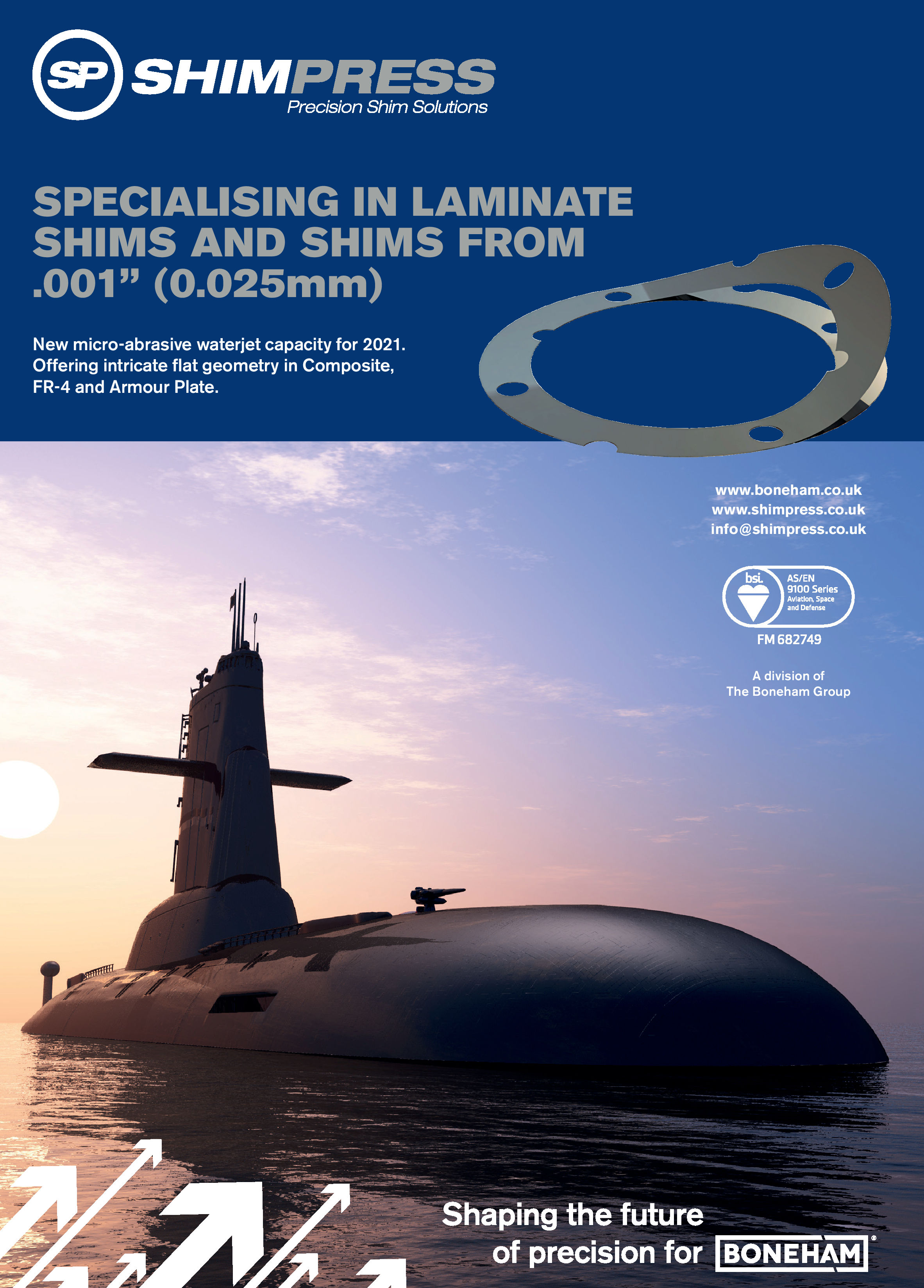

Boneham and Shimpress | Shaping the Future of Defence

17 May 2021

The May 7th announcement, that the British Defence Ministry has awarded a major contract to Rheinmetall BAE Systems Land to upgrade Challenger 2 battle tanks, is a major statement and a positive step to the return of armoured vehicle engineering to the UK.

Shaping the Future of Defence

Boneham & Turner Ltd has for over 100 years manufactured precision standard and special solutions for the defence sector, including aerospace and land vehicles. Continued investment in technology and people, has ensured the company has been able to continuously improve product offering and performance.

One such business function is the Shimpress brand. The shim manufacturing facility produces Intricate shapes in thin gauge materials to customer drawing.

What are shims and what are they used for?

Shims are a piece of metallic or non-metallic thin gauge material which, much like a washer, acts as a precise spacer between two critical parts. In manufacturing and MRO environments, shims are often used for tolerance accumulation in height, alignment and packing applications. The micro adjustment given by the use of shim helps create a level surface and can create a desired accurate fit between two mechanical parts.Boneham specialises in thin gauge shims between 0.001” (0.025mm) and 3mm. In the main for many generic applications, shims are manufactured from cold rolled mild steel like CR4/CS4. The cold rolling process gives this shim steel a smooth, even and fine finish. However, due to varying material properties, there are many options available to manufacture shims. Boneham stocks aluminium, copper, brass, stainless steel and phosphor bronze material options. Furthermore, titanium, composite, PTFE, phenolic, FR-4, armour plate and fibreglass shims can be manufactured to tight tolerances.

What are Laminate Shims?

For precise adjustments during the shimming process, Boneham manufactures peelable shims from laminate material. Laminate shims are thin layers of material bonded together to create peelable adjustments to ensure the best possible fit, both in manufacturing environments and in the field during MRO operations. Laminate shims reduce the number of shims required in stock, or onsite, whilst providing an optimum adjustment range for varying fit tolerances.What stands Shimpress by Boneham apart?

Using the latest machining technology as well as some traditional methods, Boneham can achieve tolerances of 0.01mm (0.0004”) and radii down to 0.1mm (.004”) in some of the most complex flat sheet geometries achievable. Manufacturing methods used by Boneham ensure no thermal impression or shock is placed on the material, which is associated with stress fractures later in the product lifecycle.The precise cutting of FR-4 and armoured plate, as well as traditional transmission shims in peelable form, are some of the defence solutions offered by the Shimpress brand. Full traceability, part marking, kitting and AS9100 rev D release all support a leading solution for defence and aerospace./shims-to-drawing